Cosmopack: a-eye lipstick in action on lipstick machine

One of the most anticipated novelties at the Marchesini Group Beauty booth at Cosmopack 2024 will be the innovative a-eye lipstick system by SEA Vision, paired for the first time with an automatic lipstick molding machine produced by the Cosmatic brand. From March 21st to 23rd, at Stand A9PK – Hall 19PK, visitors will have the opportunity to get up close with this technology, which recently won the innovation award at Cosmoprof in Hong Kong.

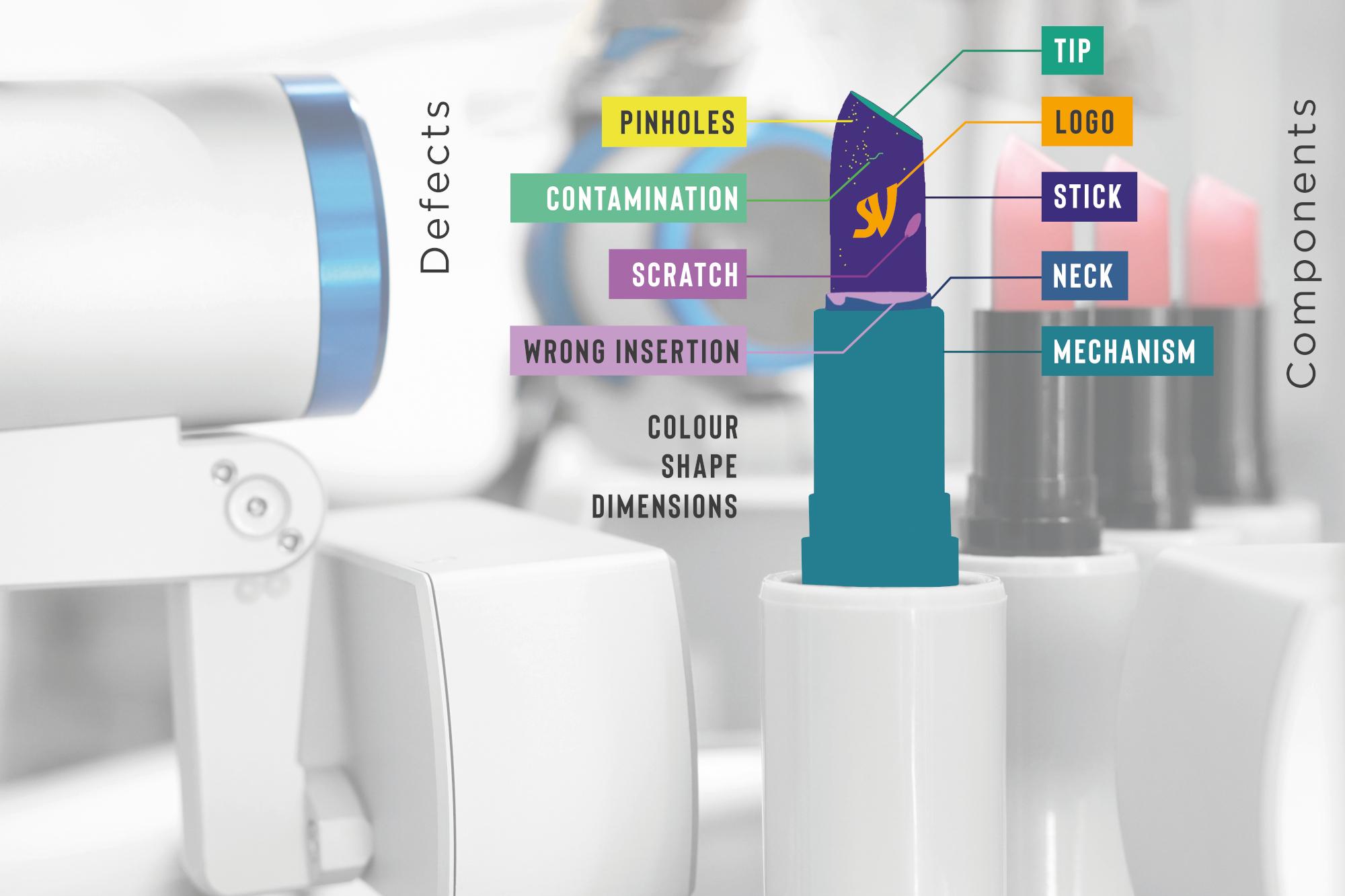

The a-eye lipstick is the world’s first system for automatic inspection of lipsticks in production based on Artificial Intelligence techniques, automating the quality inspection process that has largely relied on manual human inspection. The concept behind a-eye lipstick was developed to address a problem: the wide variety of characteristics that distinguish lipsticks (colors, finishes, shapes, formulations, and combinations) makes the inspection process complicated from the perspective of traditional artificial vision inspection systems.

The system is based on proprietary algorithms driven by Artificial Intelligence. The use of innovative neural, pre-neural, and non-neural technologies makes it possible to achieve the ideal balance between quality and inspection efficiency during the production process. State-of-the-art hardware, characterised by unprecedented ease of integration, revolutionises how quality control can be performed on 100% of the entire production without impacting timelines and ensuring unprecedented precision in evaluating the quality of these products.

Automatic lipstick machines by Cosmatic

The a-eye lipstick technology will be paired with a lipstick machine by Cosmatic, a brand of the cosmetic division specialized in the production of lipsticks and lip balms. The rotary table machine produces up to 2000 pieces/hour and is equipped with an air-cooling system up to -20°C. Thanks to a pick&place system, it will be possible to place the lipstick-filled machines on a conveyor belt to submit them to the SEA Vision inspection system. Once the inspection is completed, the lipsticks that meet the quality requirements will be automatically screwed into the appropriate screwing group.

Among the innovations in lipstick production, another Cosmatic solution: a lipstick molding machine with a production capacity of 1200 pieces/hour. The new version also includes "back filling" with the possibility of filling the machines directly from the bottom.