Corporate

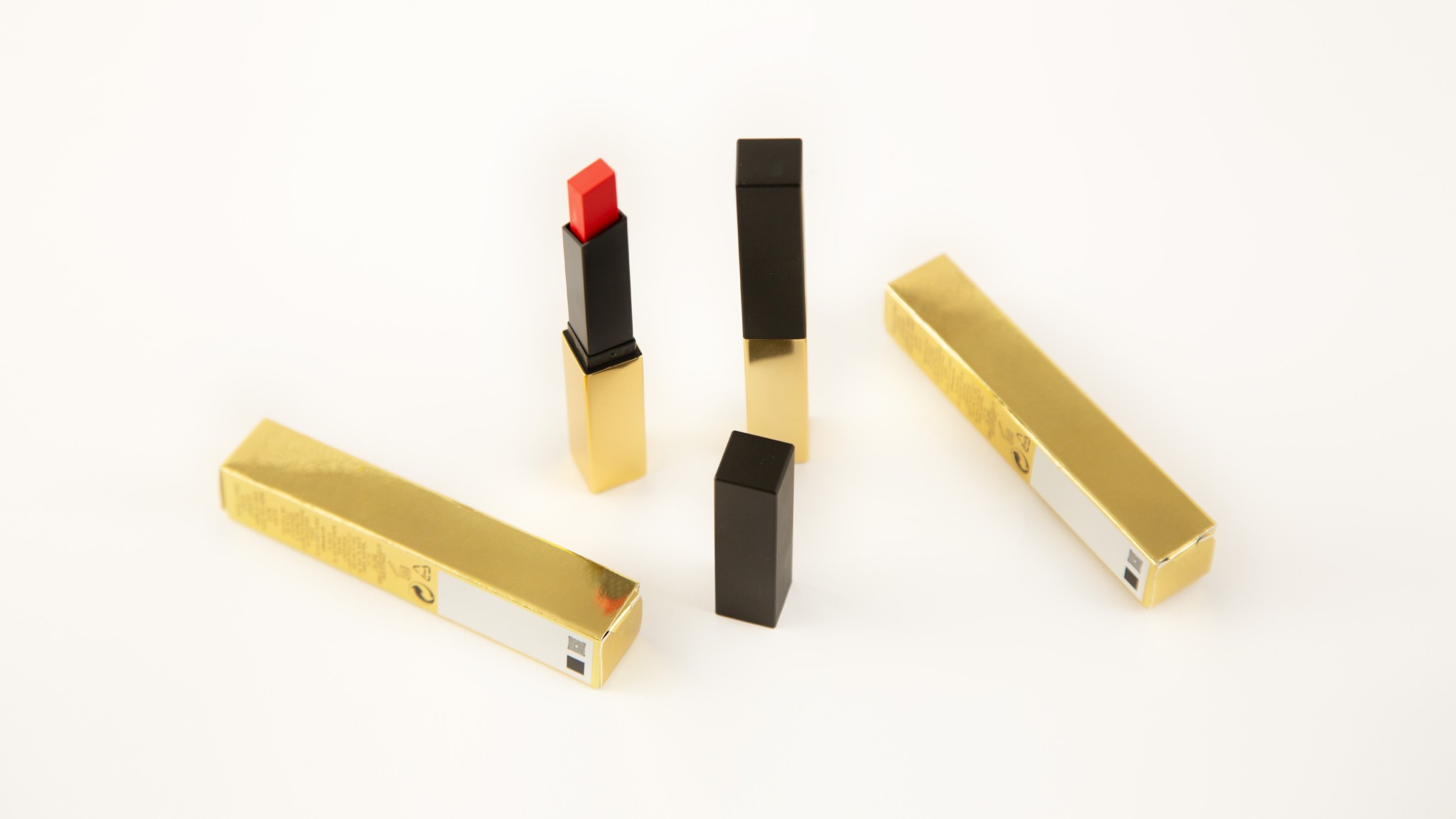

In 2020, a French company operating in the perfumes, cosmetics and toiletries business, chose us once again for the purchase of two machines - an MA 155 cartoner and an MC820 case packer respectively - to complete a high-end lipstick packaging line. For us at Marchesini Group, these long-standing partnerships are the outcome of a diversification strategy under which we have focused more and more attention on the cosmetics packaging segment in recent years, a policy also reflected by the acquisition of Cosmatic, an Italian firm specialising in lipstick production and cosmetic powder filling technologies.

The MA 155 delivered to the customer – which already owns two similar solutions purchased in the past – is able to support medium-high production rates of 120 cartons per minute, while guaranteeing outstanding quality of appearance in closing and in the overall integrity of the carton, a fundamental plus factor when packaging luxury cosmetics.

From the upstream machine, lipsticks are transferred to the plug-in boxes of the MA 155 continuous motion horizontal cartoner, one of our bestsellers well known worldwide for its versatility, ergonomics and flexibility. This machine is able to package different types of products, from ampoules to sachets, from bottles to tubes and, as in this case, lipsticks, in cartons of different shape and size.

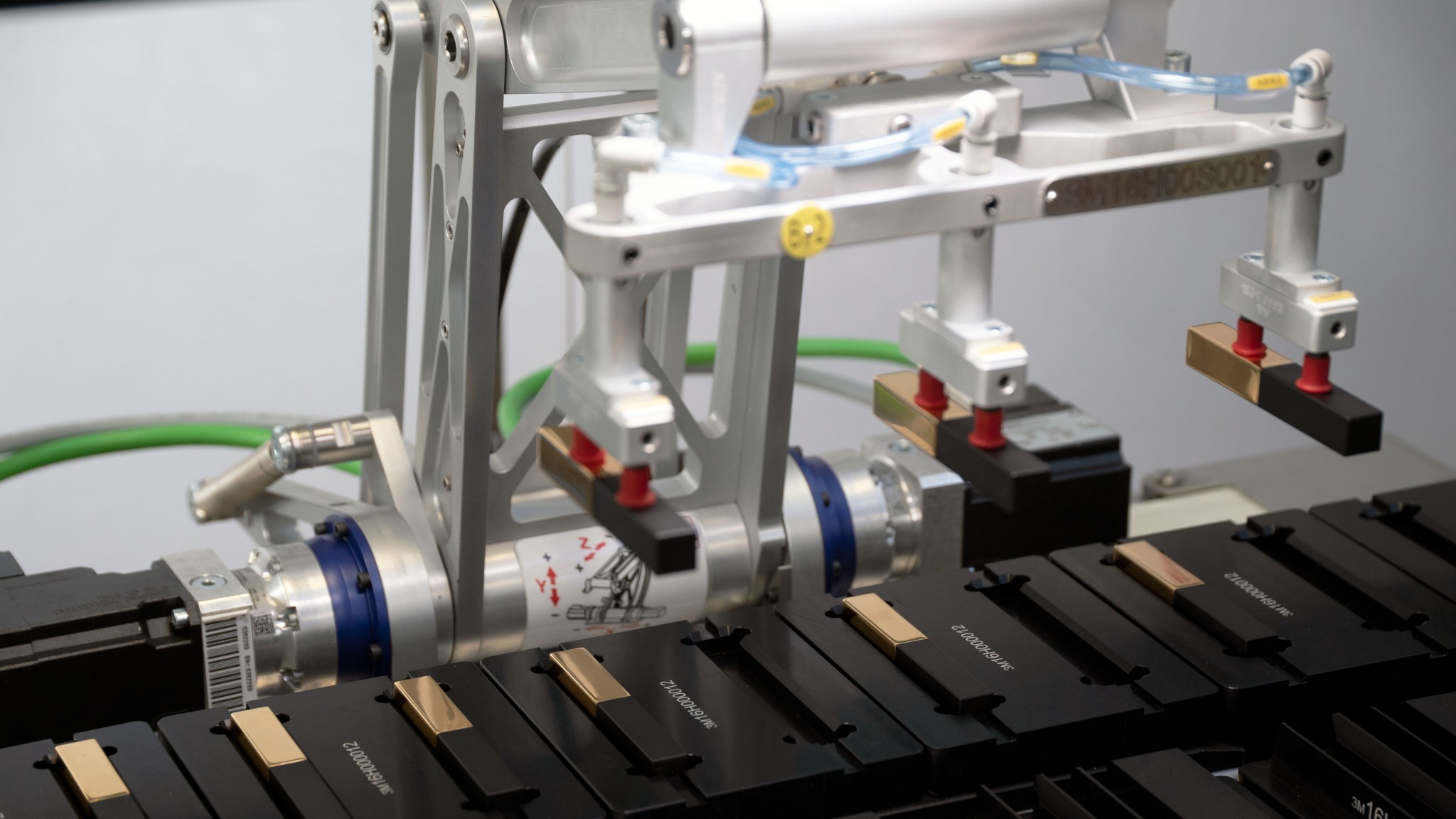

Products are robotically fed to the MA 155 by another great classic created in-house by Marchesini Group: the Robocombi, a Pick & Place robot able to pick up, transfer and, if required, bundle or stack products and packages. All this is done with no damage to the items’ physical and aesthetic integrity, an essential factor when manipulating cosmetic products.

Since 2019, the structure of the MA 155 has been further improved. This machine model now features a new control panel, a new electrical switchboard and a new pneumatic control unit, not only to upgrade its performances and versatility but also to further increase operator safety for compliance with all the latest safety regulations.

In the specific case, the MA 155 cartoner has two additional customised characteristics:

This lipstick packaging end-of-line is completed by the versatile, flexible MC 820 horizontal case packer able to process a wide range of cartons. MC 820 is ideal for Track & Trace purposes as it can be integrated with all printing, traceability and vision systems on today’s market, both for pharmaceutical tracing and for the anti-counterfeiting traceability typical of products with high market value.