MARCHESINI GROUP PRESENTS A NEW LABELLING MACHINE AND A SPECIAL MACHINE FOR LUXURY PRODUCTS

Filling and capping technologies

The focus will be on MV 545 technology by Tonazzi-Vasquali Division: a standard rotary table jar filling-capping machine. The machine is able to handle both symmetrical jars, with standard size parts, and irregularly shaped jars, by means of bushings. Various solutions are also available for the infeed of caps and jars: from manual systems using conveyor belts to semi-automatic vibrator or rotary table systems, up to robotised systems for no-touch infeed, also with automatic size change.

Alongside the standard model is a special MV 545 model, built for a cosmetics industry multinational which required a machine able to fill and cap high-end oval jars. By offering a technology able to align the positioning of the cap with that of the jar, Marchesini Group was able to significantly reduce the line’s footprint and double the previous production speed.

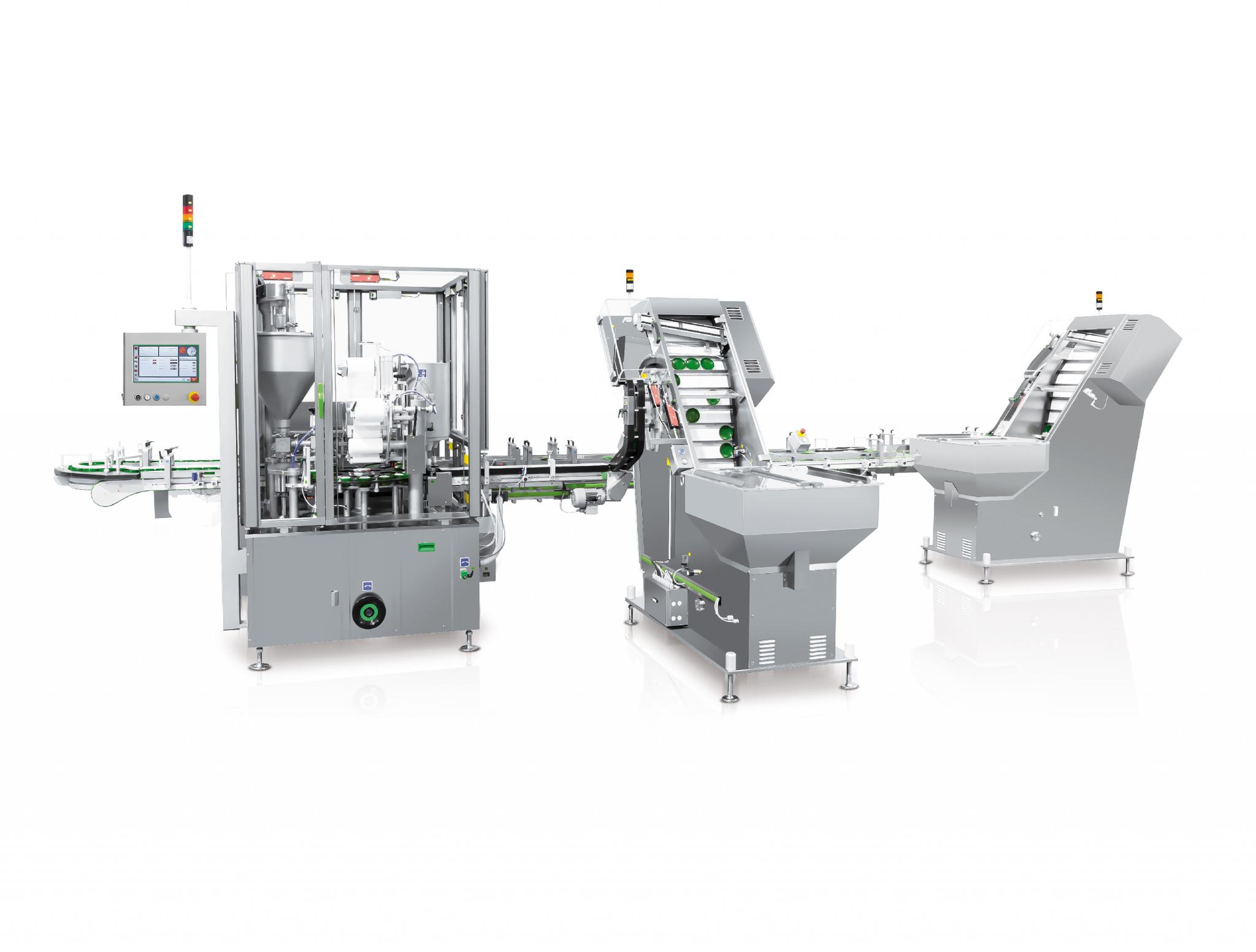

Another Tonazzi-Vasquali Division technology on exhibit is Diamante filling and capping monobloc. This machine can be equipped with a ball insertion unit to insert a steel ball in the container, a feature used in the packaging cycle of products such as lip gloss to meet the need for mixing of the solvent and product prior to application.

One of Diamante’s main strong points is compatibility with a wide variety of automatic component infeed systems, both mechanical and robotic, also in a “no touch” version. These include the Marchesini Group’s EP 6100 plate feeder, with brushless star-wheel unscrambling system and, in the cap infeed area, an automatic mechanical unscrambler by Vibrotech, the specialists in automated industrial infeed and unscrambling systems for use in automated industrial processes.

Diamante is exhibited in Ex-Proof version able to fill products containing solvents and which may generate potentially explosive atmospheres. This is a major concern for many cosmetic products, and one which the Marchesini Group handles with great care and in absolute compliance with the relevant regulatory framework, without ever sacrificing speed: Diamante works at medium-high production rates, processing up to 120 products/minute.

Cartoning technologies

No Open House would be complete without the Marchesini Group best-sellers: two MA 155 continuous motion horizontal cartoning machines which will carton bottles and tubes. Products are robotically fed to the MA 155 by another great classic created in-house by Marchesini Group: the Robocombi, a Pick & Place robot able to pick up, transfer and, if required, bundle or stack products and packages. All this is done with no damage to the items’ physical and aesthetic integrity, an essential factor when manipulating cosmetic products.

Since 2019, the structure of the MA 155 has been further improved. This machine model now features a new control panel, a new electrical switchboard and a new pneumatic control unit, not only to upgrade its performances and versatility but also to further increase operator safety for compliance with all the latest safety regulations.

Labelling technologies

The spotlight will also be on the Neri brand technologies: its market leaders – the RE 202 rotary labelling machine and the BL-A415 and SL-A210, carton labelling machines, both with serialisation systems – will appear alongside the new CL-F labelling machine, presented in two versions: a stand-alone basic model with a round bottle labelling head and a full-optional stand-alone model for labelling round and oval bottles with one or two labels, in line with a V2 engineering V150N vertical cartoner.

Wrapping technologies

Farplus C is an automatic overwrapper with a special focus on ergonomics to facilitate size change and cleaning procedures. As well as ensuring high-precision wrapping, the machine also has an internal bypass system enabling the production of unwrapped products even at very high speeds, without fitting special parts. The robotised pick-up infeed system guarantees outstanding flexibility and reliability: Farplus C is able to process single or bundled products at a speed of 80 cycles/minute and can be equipped with various options, including automatic reel splicer, tear-tape for easier package opening, reel cutting system for impeccable wrapping every time and dot or tape sealing.