Corporate

Over the past 10 years, we have been developing challenging and versatile solutions for packaging cosmetic products. One of the most impressive projects is a line for an American customer specialised in haircare products, which is capable of processing at least five different formats of hair dye colouring kits:

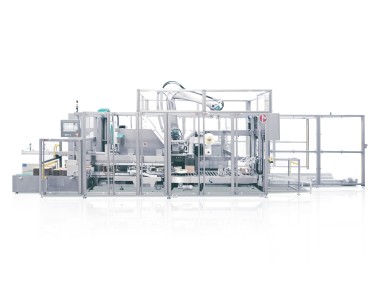

The machine upstream is the Millennium 200, which is one of our masterpieces for filling tubes of all shapes and sizes and made of different material, including metal, plastic and laminate, for both cosmetics and pharmaceuticals. This automatic double-lane linear filling machine offers numerous feeding options, which combined with the HMI for size change and simultaneous installation of different sealing systems (metal and hot air), offer incredible production flexibility.

After filling and sealing, the tubes continue along the line to a robotic station where the cards are channelled (by means of a Friction Feeder), together with the gloves in flowpack (by means of a Space Feeder) and the large brush, via an Unscrambler and a Robovision unit. Another feeding unit delivers the small brush and the instruction leaflet - for which a specifically tailored magazine has been built - directly onto the bucket chain of the cartoner MA 305.

Once assembled, the kit is put into a carton before it reaches the end-of-line automatic wrapping machine MF 910 Mini - the perfect solution for wrapping individual and grouped products - and the automatic horizontal case packer/palletizer MCP 842, which combines case packing and palletizing operations in one single and compact machine.

For kits with a large bottle, small bottle and gloves in a pod, the packaging process starts with two bottle positioners OMS120. On the conveyor belt, the bottles are positioned next to the gloves in the pod, fed along the flow by a plate lifting unit EP6100 plus a Robocombi; another Robocombi with six Pick & Place heads creates the kit by putting the components fed previously on the infeed station into the buckets of the cartoner MA 305.

For combined tube and bottle kits, the packaging process starts with two bottle positioners OMS120. Both products reach the filling syringes of two separate ML661 machines. These linear monobloc units fill the tubes and the bottles with continuous tracking movement before they are consequently sealed. Once filled, the tubes and the bottles continue towards two separate SL200/F2T automatic labellers fitted with vision cameras from our partner SEA Vision to ensure the labels are actually applied on the bottles and tubes. The next step is, again, on the kit composition station where they are packed and sent to the end-of-the-line.