Corporate

Beauty, like emotions, is a universal value. By developing this concept, Pidielle S.p.A., under its trademark Elgon, has become one of the most dynamic and creative Italian companies of the capillary cosmetic industry. At the Headquarters in Nerviano, near Milan, new product lines are developed each year (hair dyes and professional hair and skin care treatments), which are sold to over 70 countries across the world. All of Elgon’s research activities concerning colour trends always have two guidelines:

The only way to keep a winning share of the incredibly competitive cosmetics market is indeed to offer customers a well-gauged creative and technical end product for which the production procedures are straightforward and meticulous. Following this policy, Elgon has developed 200 new products over recent years, utilising cutting-edge chemical formulations inspired by the strength of natural ingredients, without ever neglecting product safety and the importance of the finished presentation packaging.

Elgon has become a renowned authority of "Made-in-Italy" on a marketplace where Italy has no other rivals. A very interesting business activity is that of social responsibility: Elgon indeed helps to create a better world by sponsoring the Sierra Leone project entitled “D as in Development. "THE FUTURE OF WOMEN IN SIERRA LEONE”. It is a literacy project on their fundamental rights managed by COOPI, an Italian independent, nonreligious and humanitarian organisation that battles all forms of poverty.

We have created three tube lines for Pidielle S.p.A. that work at a rate of 60 to 100 cartons a minutes. The latest line installed at the factory in Nerviano, where the company Headquarters are located, consists of four machines that manage the whole packaging process of hair dye tubes from start to finish. The individual strongholds of each of these machines contribute in creating an efficient, versatile and safe line capable of packaging 100 cartons a minute for a wide array of cosmetic products.

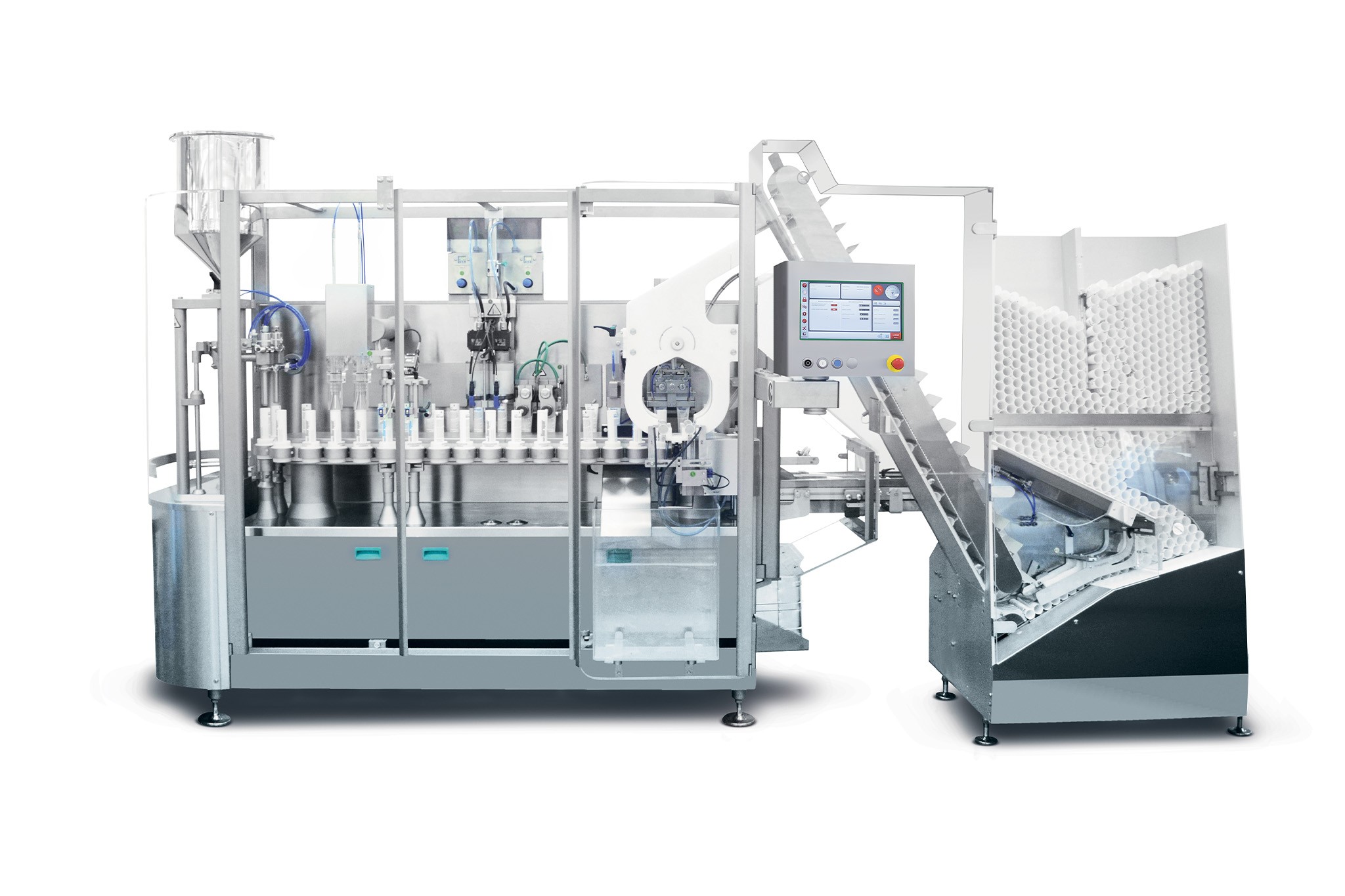

The famous Marchesini Millennium 120 made for the cosmetic industry starts the packaging process by filling and closing the tubes. Once closed, the tubes are sent to the horizontal and continuous-motion cartoning machine MA 155, which is another of our greatly successful packaging solutions.

The real operational secret of this machine lies in its incredible versatility: The MA 155 can process not only tubes, but also many other types of products, such as vials and sachets into cartons of various kinds; it can also feed additional items, even in multiple combinations, such as instruction leaflets, spoons and pipes, using custom-built infeed devices.

Once the tube has been boxed, it reaches the automatic wrapper MF 910 Mini, which wraps the cartons into bundled packs, and finally the MCP 844, the automatic casepacker-palletizer with horizontal insertion, combining the carton packing and palletizing operations into one monobloc. The MCP 844 offers customers an appealing and compact machine with features of reliability and ruggedness, which are enhanced by the use of robotic solutions that considerably increase machine performance, both in terms of speed and flexibility.